Types and Features of Soft Close Cabinet Dampers

Soft close dampers are essential components in modern cabinetry, providing a smooth and silent closing action for doors and drawers. Their selection depends on several factors, including budget, desired performance level, and installation ease. This section details the various types of soft close mechanisms available, highlighting their respective features and benefits.

Hydraulic Soft Close Dampers

Hydraulic dampers utilize a piston and cylinder filled with a viscous fluid to slow down the closing motion. The fluid resistance provides a controlled deceleration, preventing slamming and ensuring a quiet closure. These dampers are generally robust and reliable, offering good durability and consistent performance over time. Installation is typically straightforward, often involving simple screw-mounting. Noise reduction is excellent, contributing to a more refined and quieter kitchen or bathroom environment. Higher-end hydraulic dampers may incorporate advanced valving systems for fine-tuned damping control.

Pneumatic Soft Close Dampers

Pneumatic dampers use compressed air or gas to achieve a soft close effect. They offer a similar level of noise reduction to hydraulic dampers but may exhibit slightly less consistent damping performance across different temperatures or usage conditions. Installation is generally similar to hydraulic dampers. While durable, pneumatic dampers might be more susceptible to wear and tear compared to hydraulic dampers in high-use applications. The price range for pneumatic dampers can vary depending on the size and complexity of the mechanism.

Magnetic Soft Close Dampers

Magnetic dampers employ magnets and a metal plate to create a braking force that slows the door’s closing speed. These are often the simplest and least expensive option, suitable for lighter doors and drawers. However, their damping action is generally less refined compared to hydraulic or pneumatic dampers, potentially resulting in a slightly less smooth or quieter closure. They are typically easy to install but may not be as durable or long-lasting as other types, especially in high-traffic areas. Their relatively simple design contributes to their lower cost.

Comparison of Soft Close Damper Types

The following table summarizes the key features, benefits, and price ranges of different soft close damper types:

| Type | Feature | Benefit | Price Range |

|---|---|---|---|

| Hydraulic | Viscous fluid damping | Excellent noise reduction, high durability, consistent performance | Medium to High |

| Pneumatic | Compressed air/gas damping | Good noise reduction, relatively easy installation | Medium |

| Magnetic | Magnetic braking | Simple design, low cost, easy installation | Low |

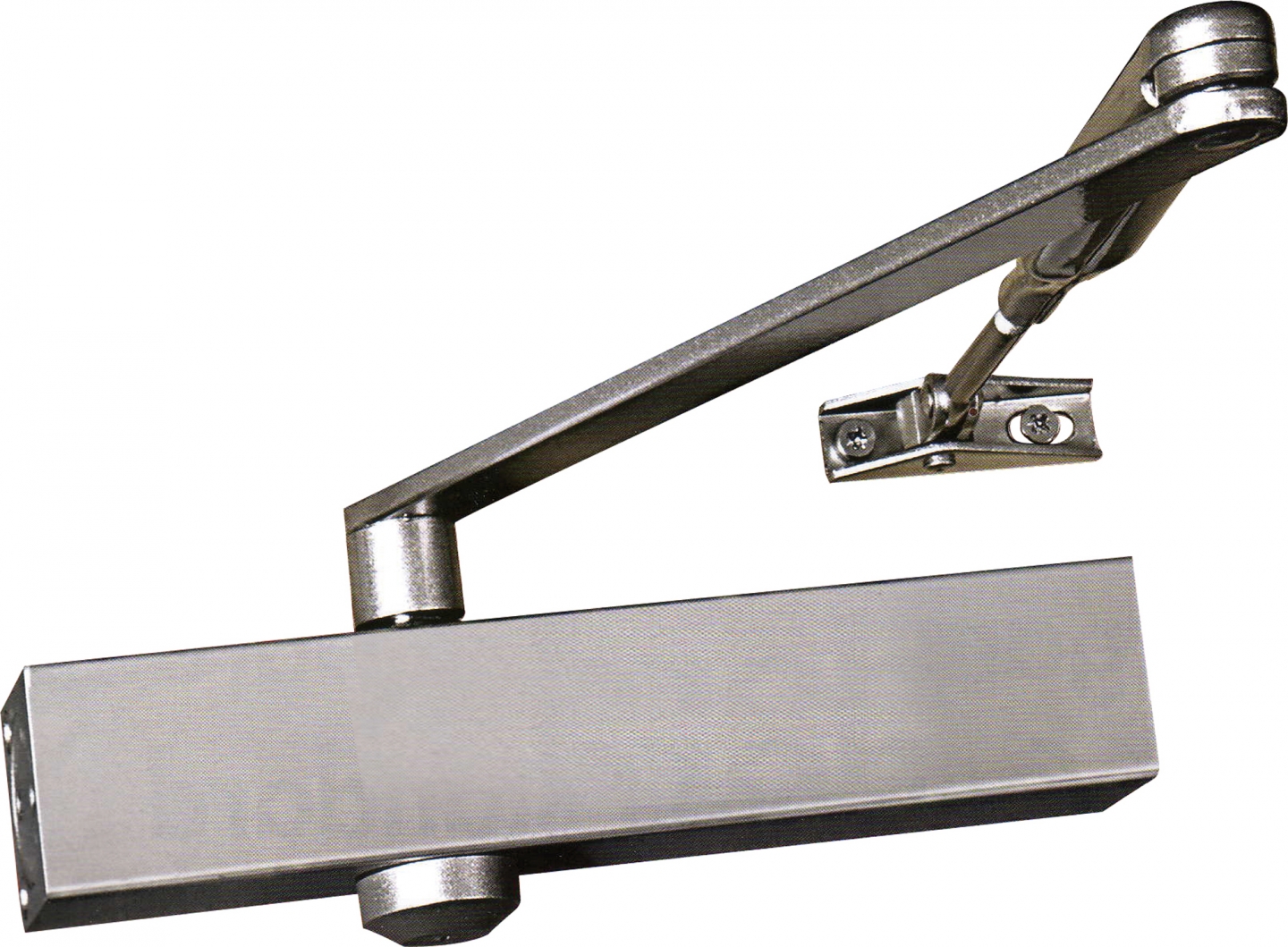

Installation and Adjustment of Soft Close Dampers: Soft Close Cabinet Door Damper

The successful installation and adjustment of soft-close dampers are crucial for ensuring smooth, quiet cabinet door operation and extending the lifespan of both the damper and the cabinet itself. Proper installation minimizes the risk of damage and ensures optimal performance, while accurate adjustment allows for customized closing speeds to suit individual preferences and cabinet weight.

Soft close cabinet door damper – This section provides a detailed guide on installing and adjusting soft-close dampers, covering common installation procedures, adjustment techniques, and troubleshooting steps.

Step-by-Step Installation Guide

The following steps illustrate the typical installation process for a soft-close damper on a cabinet door. Variations may exist depending on the specific damper model and cabinet design, so always refer to the manufacturer’s instructions.

- Identify the mounting location: Locate the appropriate position on the cabinet door and frame for the damper. This is usually near the hinge side of the door, allowing for sufficient clearance.

- Prepare the mounting surfaces: Ensure both the cabinet door and frame are clean and free of any debris or obstructions that could interfere with the damper’s function.

- Attach the damper arm to the door: Most dampers utilize a screw-based attachment mechanism. Carefully align the damper arm with the designated mounting hole on the door and secure it firmly using the provided screws. Visualize a small metal arm extending from the damper body, which will need to be attached to the door near the hinge.

- Attach the damper body to the cabinet frame: Attach the main body of the damper to the cabinet frame using the provided screws or other fasteners. This typically involves aligning the damper body with a corresponding mounting hole or bracket on the cabinet frame. Imagine the damper body, usually a cylindrical unit, being secured to the cabinet side.

- Connect the damper arm to the cabinet frame: Once both the arm and body are attached, connect the arm to the designated point on the cabinet frame, usually a small bracket or slot. This connection allows the damper to interact with the door as it closes.

- Test the damper: Gently close the cabinet door to test the damper’s function. The door should close slowly and smoothly, coming to a soft stop without slamming.

Adjusting Closing Speed and Tension

Many soft-close dampers offer adjustable closing speed and tension. This allows for fine-tuning the damper’s performance to accommodate different door weights and user preferences.

Adjustment methods vary depending on the damper model. Some dampers feature a small screw or dial on the damper body itself, allowing for precise adjustments. Turning the screw clockwise typically increases the closing force, while counter-clockwise decreases it. Other dampers may have a small lever or button that can be moved to adjust the damping effect.

For example, a clockwise rotation of the adjustment screw might increase the resistance and slow down the closing speed, while a counter-clockwise rotation would reduce the resistance and make the door close faster. Always refer to the manufacturer’s instructions for specific adjustment procedures and limits.

Troubleshooting Common Installation Issues

Addressing common installation problems ensures optimal performance of the soft-close dampers. Prompt identification and resolution of these issues prevents further complications and ensures smooth operation.

- Incorrect damper alignment: If the door closes unevenly or binds, check the damper alignment. Ensure the damper arm is properly aligned with the door and frame. Re-adjust the damper position or re-install it correctly.

- Insufficient closing force: If the door doesn’t close completely or closes too quickly, adjust the closing force by turning the adjustment screw (if available) clockwise. This increases the damping effect. Alternatively, consider using a stronger damper suited to the weight of the door.

- Excessive closing force: If the door closes too slowly or with excessive resistance, adjust the closing force by turning the adjustment screw (if available) counter-clockwise. This reduces the damping effect.

- Stripping of screws: If screws strip during installation, use screws of a larger diameter or use wood glue to reinforce the mounting holes before reinstalling the screws.

- Interference with other components: Ensure the damper doesn’t interfere with other cabinet hardware, such as hinges or drawer slides. If interference occurs, adjust the damper position or consider using a different damper model with a more compact design.

Maintenance and Repair of Soft Close Dampers

Proper maintenance significantly extends the lifespan of soft close dampers, preventing premature failure and ensuring smooth, quiet operation of your cabinets. Regular cleaning and lubrication are key aspects of preventative care, while understanding common failure points allows for timely repairs or replacements.

Preventative Maintenance of Soft Close Dampers

Regular cleaning and lubrication are crucial for maintaining the optimal performance of soft close dampers. Dust, debris, and sticky substances can hinder the smooth operation of the internal mechanism, leading to reduced efficiency and eventual failure. At least once a year, carefully wipe the damper mechanism with a soft, slightly damp cloth. Avoid using harsh chemicals or abrasive cleaners. After cleaning, apply a small amount of silicone-based lubricant to the moving parts of the damper. This lubrication minimizes friction and ensures smooth, consistent operation. This preventative measure significantly prolongs the life of the damper and prevents unnecessary wear and tear. Regular visual inspections for any signs of damage or wear are also recommended.

Common Causes of Damper Failure and Repair Procedures, Soft close cabinet door damper

Several factors can contribute to soft close damper failure. Excessive force applied to the cabinet door, often due to forceful closing or impacts, can damage the internal components of the damper. This can manifest as a slow closing speed, a jerky motion, or complete failure to close softly. Another common cause is the accumulation of dirt and debris, which can impede the smooth movement of the damper mechanism. In such cases, thorough cleaning and lubrication are often sufficient to restore functionality. However, if the damage is more significant, such as a broken piston or a damaged spring, replacement may be necessary. To repair a faulty damper, carefully remove the damper from the cabinet door. Inspect the components for damage. If the problem is simply dirt and debris, clean and lubricate the mechanism. If the damper is damaged beyond repair, replace it with a compatible model. This replacement process typically involves removing the old damper and attaching the new one using the existing mounting hardware.

Choosing Replacement Soft Close Dampers

Selecting a suitable replacement damper requires careful consideration of compatibility with existing cabinet hardware. The mounting holes, piston size, and overall dimensions must match to ensure a proper fit. Always check the manufacturer’s specifications to ensure compatibility. Consider the closing force and speed requirements for your specific cabinet doors. Heavier doors require dampers with higher closing force ratings. When choosing a replacement, note the damper’s length and the mounting hole spacing. These dimensions must align precisely with your existing cabinet hardware to ensure a secure and functional installation.

Replacement Damper Options

The following table compares different replacement damper options. Note that pricing and availability can vary based on retailer and specific model.

| Manufacturer | Model | Compatibility (Cabinet Type/Door Weight) | Approximate Cost (USD) |

|---|---|---|---|

| Blum | BLUMOTION (example model number) | Euro-style cabinets, doors up to 20 lbs | $10-15 |

| Hettich | Silent System (example model number) | Frameless and framed cabinets, doors up to 25 lbs | $12-18 |

| Salice | Soft Close (example model number) | Various cabinet types, doors up to 22 lbs | $11-16 |

| Hafele | Motion Technology (example model number) | Overlay and inset cabinets, doors up to 25 lbs | $13-19 |